Safe REPAIRS

Not all wheels should be repaired! AWRS uses definitive criteria to determine if a wheel qualifies for repair. Industry standard inspection techniques are used to qualify all wheel surfaces. A wheel with bent or cracked spokes, cracked or elongated lugholes, cracks in the mounting surface, or cracks in the valve steam or bead seat will not be repaired. All repaired wheels are marked and can be tracked for accountability. Every wheel reinstalled on a vehicle by AWRS technicians are mounted to manufacturer specifications. CONTACT US

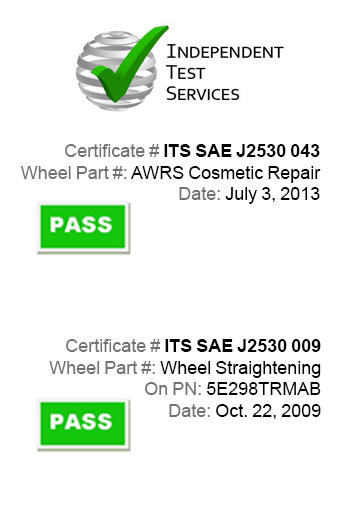

SAFETY THROUGH TESTING

AWRS is committed to making consumer safety our first priority. Wheels bent and cosmetically repaired using AWRS standard procedures were tested at an independent laboratory. The repaired wheels were tested to the specifications of the respective vehicle manufacturer for Dynamic Radial Fatigue, Cornering Fatigue, Lateral Impact, and Marking Standards. These standards use the same performance criteria required for the OEMs. Every wheel met or exceeded all performance criteria.

TRAINING & CERTIFICATION

AWRS technicians receive comprehensive training in all aspects of the wheel repair process. They must show the required knowledge of wheel construction, heat treatment of aluminum alloys, straightening, repairing, refinishing and polishing. They must also demonstrate their knowledge and understanding of the safety criteria used to determine when a wheel can safely be repaired. Finally, they are required to complete their certification before performing authorized wheel repair services to meet AWRS standards.

BECOME AN AWRS INSIDER!

Sign up to receive monthly promotions, specials, news and more!